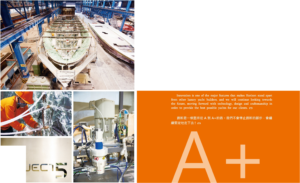

As Asia’s leading yacht builder, Horizon Yachts continues to invest in R&D, new technology and equipment.

This article is taken from the official Horizon Yachts publication (volume 32 Winter 2014) in which Chris Chen describes the technical collaboration between Horizon’s specialised composites corporation Atech Composites and Composite Integration Ltd.

Innovation is and always will be a core value for Horizons sustainable development.

As Asia’s leading yacht builder, Horizon Group has continued our investments in research and development, technology and equipment throughout the years; not only to build high-quality, reliable yachts for our owners, but also to be an innovative leader in our industry and the lead the way in yacht manufacturing technology.

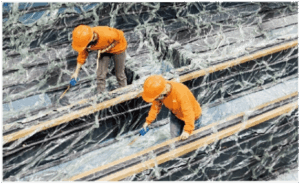

When many shipyards were still using traditional hand lamination to produce hulls, Horizon established a specialised composites corporation, Atech Composites, in 2000 to help increase the strength, integrity and safety of our hull structures. Horizon’s Atech facility began using the patented SCRIMP “vacuum infusion” technology in manufacturing one-piece hulls and became the first shipyard in Asia to utilise the procedure.

In 2004, Horizon developed an improved the resin infusion technology, which transforms the resin from its original 2D flow on surfaces to 3D flow. 3D flow allows the resin to climb up and down internal stiffeners, enabling the construction of far larger structures than previously possible. By utilizing the new infusion technology, the resin can flow in all directions instead of only in a planar direction, and the stiffeners can be integrated with the yacht during the infusion process, making the yacht both stronger and lighter. In 2005, Horizon broke the world record with a 136-foot hull and stiffeners infused in one shot utilising this improved 3D infusion technology.

In 2009, Horizon was authorized by The European Aeronautic Defence and Space Company N.V (EADS) through SAERTEX for another advanced process technology called Vacuum Assisted Process (VAP). YAP is a breakthrough technology that was originally developed for application in aircraft manufacturing, but the technology can now also be applied to yacht manufacturing. Without sacrificing the benefits of SCRIMP, VAP can more uniformly distribute resin and guarantee less air trapped within the composite.

In order to produce safer, lighter and stronger hulls, while also shortening the time it takes to complete resin vacuum infusion, Horizon Group continued the innovative path forward and collaborated in 2013 with the British company Composite Integration Ltd to develop large-scale automatic resin infusion equipment that is custom made for Horizon’s requirement.

Composite Integration Ltd has many years of experience in the development of equipment and control systems for resin transfer moulding (RTM) processes. More than a “machine builder”, Composite Integration Ltd is also dedicated to advancing the composite processing technology by working closely with customers to develop a unique resin infusion machine and to further refine the associated technology. Their ‘Direct Infusion’ process was originally developed and fine-tuned with large-scale marine applications, but the technology has now been recognised by the wind and tidal energy sectors as being very relevant to the manufacture of large scale turbine structures.

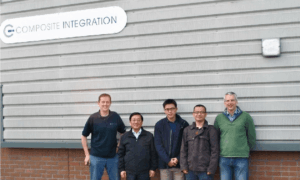

After a year of development, Horizon’s custom automatic vacuum infusion equipment was completed in September 2014. This equipment uses the CIJECT 5 machine as a “parent model” to fine-tune and tailor the vacuum infusion process to meet with Horizon’s demands. Horizon sent two infusion engineers to Composites Integration Ltd in the UK for a professional training program to learn the CIJECT 5 capabilities, operation, assembly, calibration and the theory of its mechanics.

Using the CIJECT 5 to implement vacuum infusion has the following advantages:

- By use of the precise pressure control and flow control during the resin infusion process, the maximum infusion flow rate can reach 27 litres per minute, greatly enhancing manufacturing efficiency.

- During the infusion process, the proportion of catalyst, the resin flow and infusion pressure can be precisely controlled, and perfect the output to ensure the quality of the product.

- All of the data produced during the infusion process, including temperature and humidity, infusion flow, infusion pressure, total infusion etc can be continuously logged and process control methodology can be consistently maintained. This is extremely helpful for product quality tracking and analysis of manufacturing parameters to further improve the process and enhance the efficiency.

The CIJECT 5 uses feedback from In Mould Pressure Sensors (IMPS) to monitor the pressure inside the infusion mould and to automatically control the output of mixed resin. These sensors also provide accurate feedback and ensure that the infusion is controlled at the optimum parameters. This technical approach has been proven to provide significant technical advantages, not only in ensuring an efficient infusion process but also in the resulting laminate quality.

The infusion machine is very smart and can automatically adjust the mix ratio of resin and catalyst according to the gel time required (i.e. the time to make resin transform into a gel like status). In addition, the resin and catalyst are thoroughly mixed automatically inside the mix-head before being dispensed into the infusion assuring the perfect resin ratio. After the infusion is completed, the operator just needs to press a switch and then the mix head, injection valve and associated pipe-work can be cleaned automatically by activating the machines flushing process. Also due to the high pressure flushing the cleaning agent required is less than 1/10 of the original, greatly reducing environmental pollution.

Vacuum infusion is well-known as one answer to the environmental problems normally associated with large scale composite manufacturing, and it can reduce the emission of Volatile Organic Compounds (VOCs) to nearly zero. The use of the CIJECT 5 equipment to automatically dispense mixed resin on-demand significantly reduces the environmental impact by decreasing waste and allowing efficient clean up after the infusion. This investment improves product quality but also helps decrease environmental impact.

The CIJECT 5 is now part of Horizon Group’s high tech capabilities in producing FRP products to the highest quality standards, through the automatic control of pumping, mixing and dispensing of two-part thermosetting resin. In 2014 Horizon successfully infused a 110-foot hull with its longitudinal girders and transverse frames in a single shot by using this new automatic infusion, and all structural components are as flawless as well as being lighter and stronger.

“ Our collaboration with Composite Integration Ltd has ensured Horizons place as the first shipyard in Asia, and only the second yacht manufacturer in the world, to use automatic resin infusion equipment to produce yacht hulls. Composites Integration Ltd has also been inspired with additional ideas to develop new equipment, thanks to Horizon’s wealth of practical experience in vacuum infusion. “