CI Library

Composite Education at Your Finger Tips

Browse by Resource Type:

Datasheet = CIJECT 8

High performance 3 component resin mixing and injection machine. Multi programmable recipes, component flow meters and IMPS.

Datasheet – IMPS Readout Unit

- The IMPS readout unit is designed to provide sensor power and display pressure reading in bar.

Datasheet – CIJECT 5

For large scale direct infusion. High precision 2 component gear pumps with PID feedback flow control. Flow rates from 0.1Kg/min to 30Kg/min.

Datasheet – CIJECT 4

Robust machine for high flow applications, 200cc double acting piston pump to achieve 20Kg/min.

Datasheet – CIJECT 3

Advanced pressure-pot machine for pre-mixed or single component resin systems.

Datasheet: Catch-Pots

Catch-pots: essential in protecting your vacuum systems from excess resin during infusion processes.

Datasheet – Mould Seals

A comprehensive range of mould seals and “formers” used in the tool making process.;

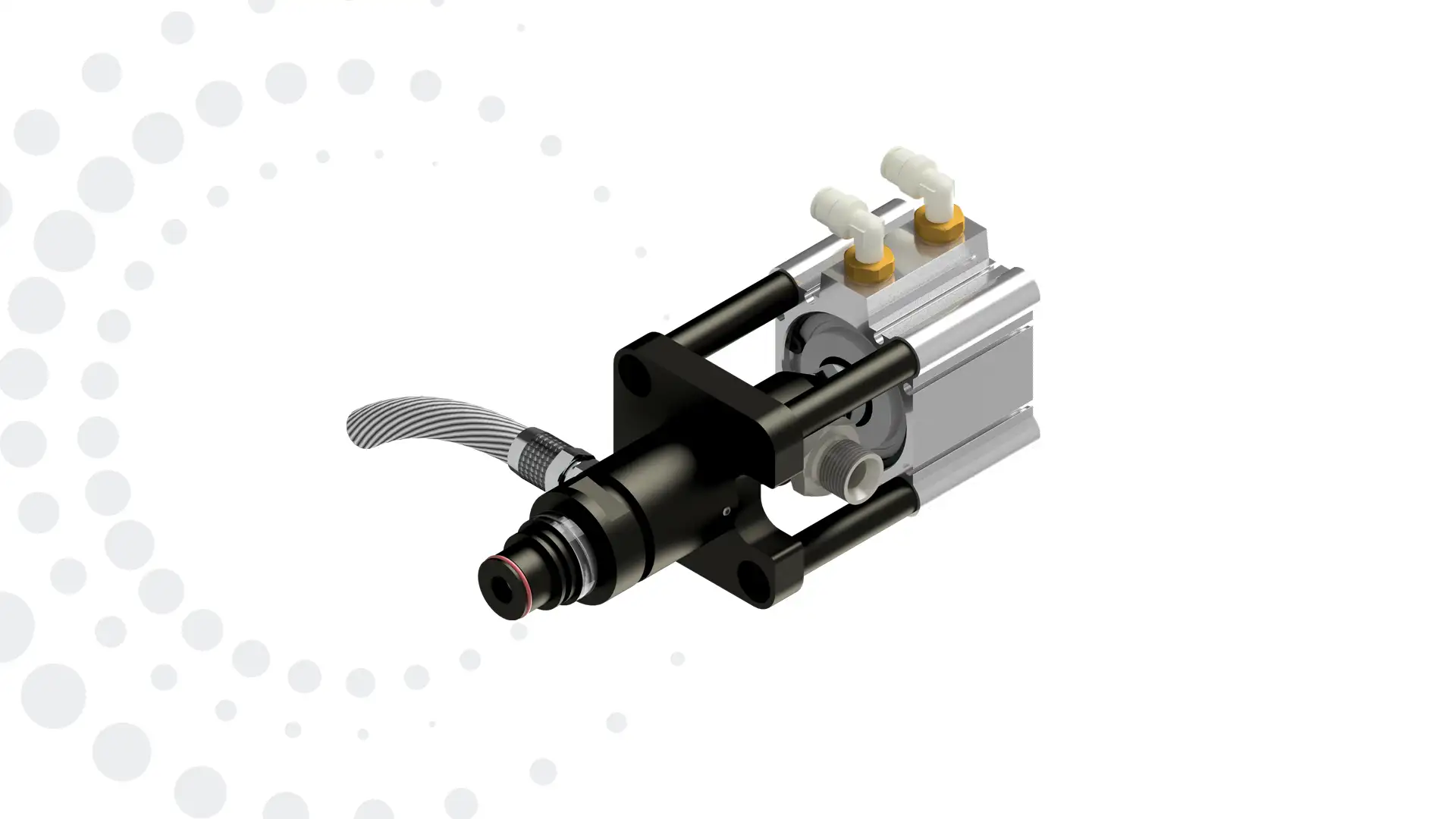

Datasheet: Injection Valve

CI injection valves ensure vacuum-tight seals and easy isolation for closed moulds, with automated functionality for reduced operator effort. Robust design enhanches reliability and performance.

Datasheet: CIVAC 3

Dry-running vacuum system, suited for medium to large RTM & Direct Infusion.

Datasheet: CIVAC 2

Oil filled system suited to small/medium Direct Infusion applications.

Datasheet: CIJECT SC4

3 component machine, to spray/dispense silicone with a 1:1 mix ratio and thixotropic additive.

Datasheet: CIJECT SC2

Dispense/spray silicones at 1:1 mix ratio. 2×25 litre material tanks.

Datasheet: CIJECT SC1

Portable machine, to dispense/spray silicones at a 1:1 mix ratio. 2×2.5 litre material tanks.

Datasheet: CIJECT 2

Advanced 2 component resin mixing & injection machine, for high levels of control and verification.

Datasheet: CIJECT 1

2 component machine, programmable recipes, alarm monitored gel timer – for RTM/Infusion.

Datasheet: CIJECT 0

Entry level, 2 component resin mixing & injection machine for RTM & Infusion.