Author:

Lower wing skin, Wing of Tomorrow – Composite Integration | Innovation in Composites Technology

CI wins Manufacturer of the Year award

Composite Integration, the resin transfer moulding and resin infusion specialist, has announced that it has been named Manufacturer of the Year 2019 at the Cornwall Manufacturers Group (CMG) Awards.

Continued Growth Leads to Composite Integration Site Expansion

Continued Growth Leads to Composite Integration Site Expansion

Composite Integration is delighted to announce its move to a new state of the art facility as a result of its phenomenal growth over recent years, which has seen the workforce and its capabilities increase. The company moved to the new site in Saltash, UK on August 23rd 2019 with the grand opening planned for later this year.

Structural Science achieve excellence with CIJECT® equipment

Structural Science Composites Limited (SSC) draw on over 20 years of experience to produce the ultimate in durable, composite manhole covers. Built using patented ‘ThruBeam®’ technology, these covers offer excellent strength and durability, suitable for use in a number of loading environments.

Launch of CIJECT 3 Range – Equipment for Advanced Composites

Launching the new CIJECT 3 range for advanced composites at JEC 2018

Composite Integration appoints distributor in India

Kelly Ellis and Stephen Leonard-Williams of Composite Integration exchange contracts with Nandan Reddy and Sunil Yallapragada of Triobotics

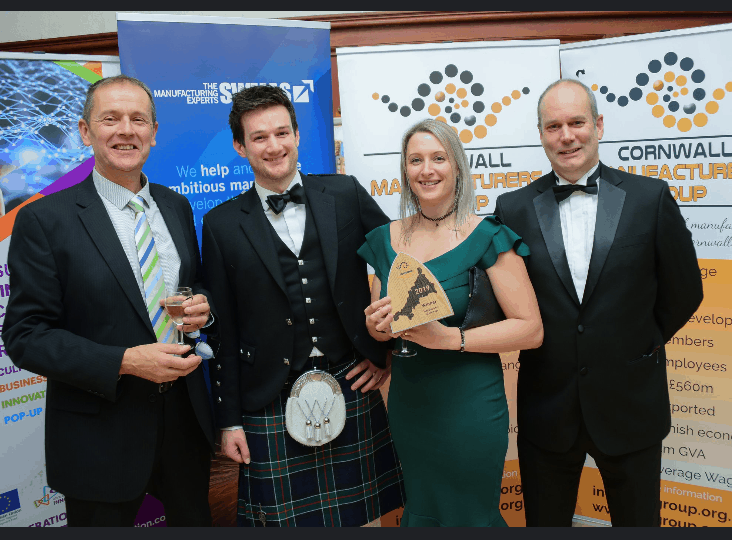

Composite Integration wins Exporter of the Year and Innovation Awards

Composite Integration win Exporter of the Year and Innovation Awards!

We are delighted to announce that we have won the awards for both Innovation of the Year and Exporter of the Year in the CMG manufacturing awards.

This reflects both our continual growth as a leading supplier of processing solutions into world-wide markets but also our innovative work to meet new challenges in the aerospace sector.

We owe a huge ‘Thank You’ to our truly exceptional team for all their dedication and hard work over the last couple of years!

Following is the CMGs press release about the event.

INSPIRING LEADERS HONOURED AT MANUFACTURING AWARDS

Last night the winners of the biennial Cornwall Manufacturers Group awards were announced, recognising the very best and brightest of manufacturing talent in the county.

Top business leaders, exporters, apprentices, community projects and innovations were celebrated at a special ceremony hosted by Mike Rigby, UK Head of Manufacturing for Barclays and attended by over 150 of the counties business leaders and manufacturing pioneers.

This year’s competition saw an exceptional quality and number of entrants with the judges, chaired by Mel Colton-Dyer, Chief Operating Officer at the Cornwall Chamber of Commerce praising the fresh, young talent seizing the opportunity to work in the rewarding and valuable manufacturing sector.

There were three finalists in each of the six award categories with the winners as follows:

• Business Leadership Award – Richard James, Director of Hewaswater Engineering, St Austell

• Manufacturer of the Year – Spiral UK, Helston

• Apprentice of the Year – Samual Weedon from Daften Die Casting, Wadebridge

• Environmental/Community Project – Polymermedics, St Austell

• Innovation of the Year – Composite Integration, Saltash

• Exporter of the Year – Composite Integration, Saltash

The awards headlined by Barclays were sponsored by Lloyds, SWMAS, Exelin, Truro College, Foot Anstey, Bishop Fleming, Cornwall College and Cornwall Chamber of Commerce.

Eric Nicholls, chair of the Cornwall Manufacturers Group concluded,

“Tonight has been a great success, not only for the winners and finalists but for manufacturing as a whole. This event showcases our vibrant and diverse sector, shines a spotlight on the increasingly national and international role Cornwall’s manufacturers play and escalates the recognition by business leaders of the importance of manufacturing to Cornwall’s economy.”

Composite Integration at the NEC Advanced Engineering Exhibition

We return to the Advanced Engineering show at the NEC for our fifth year from 1-2 November introducing our expanding business development team and announcing continual investment in new technologies which has seen the business grow by 280% in the past five years.

With the recent reporting that UK manufacturing output has moved up one spot from 9th to 8th in the 2017 global league table, Composite Integration has mirrored the thriving manufacturing sector with our advanced engineering business witnessing growth in their multi-industry specialist sector.

Innovators in RTM and Resin Infusion, providing a market leading range of equipment and services to a continually evolving global customer base including marine, wind energy and the aerospace sectors, Composite Integration deliver a fully integrated service from process development to production solutions, tailor made to suit requirements.

Stephen Leonard-Williams, Director says: “Investing in the show with a larger, bespoke stand reflects our commitment to the Advanced Engineering sector and our dedication to continue to deliver market leading solutions to the composites industry.

We are expanding our engineering and design team to keep pace with the growth in demand from the aerospace sector. Our newly formed Business Development Department will work alongside the technical team to ensure enquiries are dealt with efficiently and new opportunities explored to the full.

We are continuously diversifying into new market areas and welcome the challenge of excelling in extreme environments, demanding the very best of what we do. We’re hopeful that the show will demonstrate our experience and capabilities, propelling the business further on the growing trajectory forecasted.”

We will be on stand L140 and invite everyone interested in our unique systems, based on years of R&D, to visit us and discuss how we can deliver a solution for you.

As always, we look forward to making new contacts and meeting old friends.

Unique composite ‘Run-Flat’ system with RTM by Carbon ThreeSixty

Composite Integration customer Carbon ThreeSixty are a specialist carbon composites company providing partners with R&D and prototype manufacture infrastructure that delivers bespoke specification wheels and runflats.

The company recently partnered with a leading defence sector wheel system provider to develop concepts and demonstrate manufacturing readiness for a next generation lightweight runflat protection product, comparable to those widely used to provide escape & evade capability to land defence vehicles such as armoured personnel carriers.

The existing system consists of a transfer-moulded rubber body, reinforced with a central steel spine and fasteners. Carbon ThreeSixty developed a cored thermoset composite component that met or exceeded the performance of the existing offering, whilst dramatically reducing the mass from 26 Kg to 12.5 kg, a reduction of over 50%.

Carbon ThreeSixty Ltd harnessed the exceptional performance of advanced carbon composite materials, and through expert application of high value manufacturing techniques such as dry-fibre preforming technologies and resin transfer moulding were able to deliver a solution that met the client’s price expectation and production volume requirements.

Composite Integration supplied the CIJECT 2 RTM equipment used in the development and production of the moulded components and assisted with general technical support where necessary.

Click Here to visit the Carbon ThreeSixty website