Standard Equipment

RTM, HP-RTM & Infusion Equipment for Professional Production

Production-Ready Systems for Qualified Composite Manufacturing Environments

Our standard range includes CIJECT injection machinery for RTM, VRTM, HP-RTM and infusion, together with CIVAC vacuum systems, monitoring and QA solutions, tooling and essential ancillaries for professional composite manufacturing environments. Designed for repeatability, process control and long-term reliability, these systems are used in high-value and safety-critical composite programmes across aerospace, wind energy, marine, defence, automotive and industrial sectors.

Browse the sections below to explore CIJECT, CIVAC and further equipment and accessories engineered for consistent, compliant and efficient composite production.

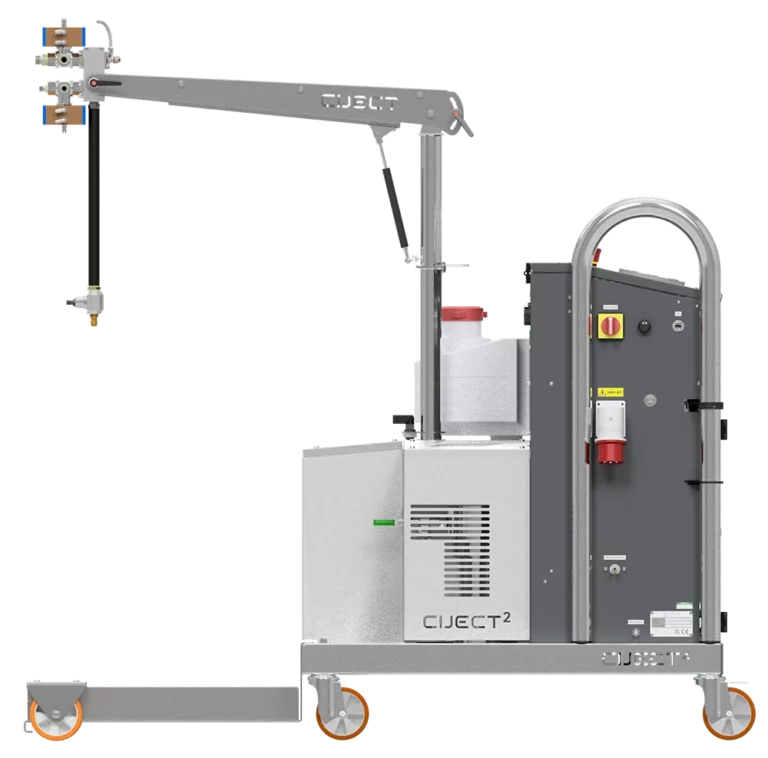

CIJECT® injection machinery for RTM, VRTM, HP-RTM and infusion, specified for precision, repeatability and stable long-term production.

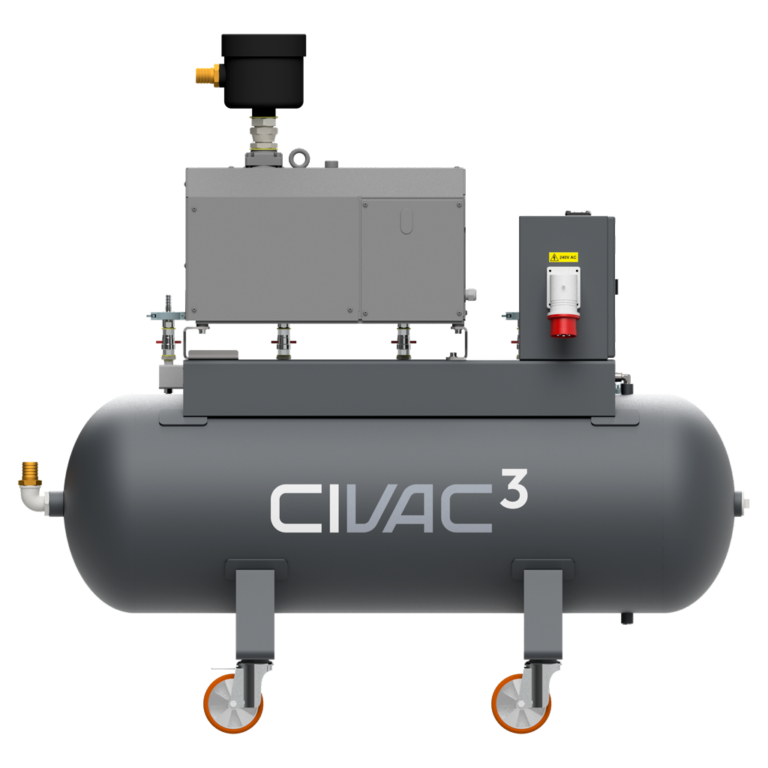

CIVAC vacuum pumps and ancillaries for RTM, VRTM and infusion, including components for vacuum supply, connection, control and measurement throughout the process.

CIJECT® SC machines for controlled silicone dispensing and spray applications, with fixed-ratio 1:1 or 10:1 configurations and positive displacement pumping for consistent, reliable operation.

Lab & Testing Equipment

Instrumentation, data logging and laboratory test equipment for composite research, process validation and development trials.

Composite

Tooling

Accessories

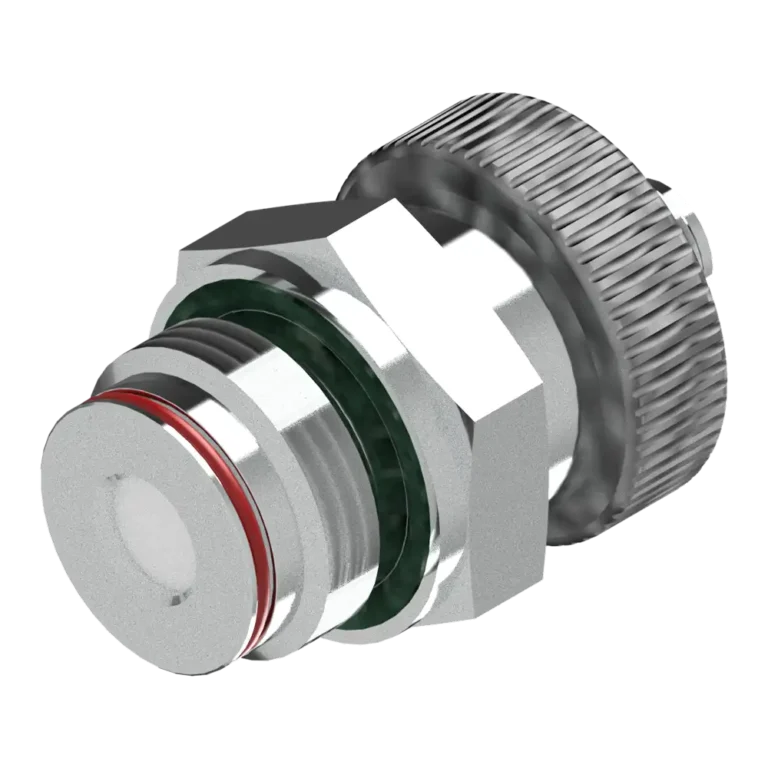

Composite tooling accessories for RTM, HP-RTM and infusion, including connectors, seals, lines and control components for reliable mould operation.

Metal

Tooling

Accessories

Metal tooling accessories including inserts, alignment, sealing and connection hardware engineered for RTM, HP-RTM and infusion.

Direct

Infusion

Accessories

Accessories for Direct Infusion processes, including flow media, lines, connectors and control components engineered for consistent wet-out and stable vacuum integrity.